Services

......Call

the Specialists

We know the problems and how to solve them because we are

specialists in Industrial Cleaning and Coatings.

| List of Services: |

Ask us about:

- Machinery Degreasing

- Corrosion Resistant Coating Systems

- Conventional or Airless Spraying

- Ultra High Pressure Water Blasting with or without Abrasives

- Interior Steam Cleaning

- Plant Safety Painting

- Fire Clean-up

- Smoke, Carbon, Oxide Removal

- Masonry Dyeing

- Sandblasting

We work around your plant production schedules. We have the proper people and machinery to perform all work in a professional manner. We will be happy to estimate all jobs quickly. Contact us for a quote or for more information.

- Steel Finishing

-

Following a white metal blast, tank interiors are coated with the specified epoxy or other lining. Exteriors are blasted, primed, and finished to specification.

Following a white metal blast, tank interiors are coated with the specified epoxy or other lining. Exteriors are blasted, primed, and finished to specification.We specialize in cleaning and coating all types of steel, and non-ferrous metals, from structural steel to tanks to piping to lighter gauges. We have a three building plant, with capacities for any size you can ship. Your schedule becomes ours. Work can be cleaned and painted at your plant or ours.

Structural steel beams abrasive blasted, primed with inorganic zinc, intermediate coated with high build epoxy, and finished with catalyzed polyurethane.

- Compressor Refinishing

-

Exteriors are carefully abrasive blasted, solvent cleaned, and surface defects are filled and smoothed. Compressors are carefully abrasive blasted, removing all rust old coatings, and mineral deposits.

Exteriors are carefully abrasive blasted, solvent cleaned, and surface defects are filled and smoothed. Compressors are carefully abrasive blasted, removing all rust old coatings, and mineral deposits.Interiors are coated with high temperature corrosive resistant finish, to OEM specifications. Exteriors are primed and finish coated with polyurethane, to original OEM colors or your choice.

- Corn Cob Blasting

-

A non-abrasive method of cleaning, paint removal, and preparation for new coating application. Call, write, or fax us for a quotation on any cleaning, blasting or painting work you may have.

A non-abrasive method of cleaning, paint removal, and preparation for new coating application. Call, write, or fax us for a quotation on any cleaning, blasting or painting work you may have.

- Increased Lighting

-

We specialize in brightening your production area. A thorough cleaning, followed by the application of high light reflectance (93%) industrial coating, can more than double the available light.

We specialize in brightening your production area. A thorough cleaning, followed by the application of high light reflectance (93%) industrial coating, can more than double the available light.We are a Franklin Park company, and have been in business for over thirty years. Many of your neighbors have contracted with us to make their plants brighter, safer, and more productive. May we Quote you?

- Machinery Refinishing

-

We specialize in cleaning and refinishing new and used machinery. A new multi-pump header, with control console, mounted on a skid, completely prepared to NACE #1 White Metal, epoxy primer at 5 mils DFT, and 5 mils DFT of catalyzed polyurethane.

We specialize in cleaning and refinishing new and used machinery. A new multi-pump header, with control console, mounted on a skid, completely prepared to NACE #1 White Metal, epoxy primer at 5 mils DFT, and 5 mils DFT of catalyzed polyurethane.Non-ferrous metal received special bonding primers. Speed reducers, abrasive blasted, coated with MIL spec epoxy primer, finish coated with CARC enamel. Reducers weigh 8,500 pounds each. Large, bulky sizes are no problem. Call for an estimate at no charge.

- Presses Refinished

-

We specialize in cleaning and coating all types of printing equipment. Your schedule becomes ours. Presses can be cleaned and painted at your plant or our shop in Franklin park. Only safe cleaning agents, corn cobs, and hand tools are used to thoroughly clean without damage.

We specialize in cleaning and coating all types of printing equipment. Your schedule becomes ours. Presses can be cleaned and painted at your plant or our shop in Franklin park. Only safe cleaning agents, corn cobs, and hand tools are used to thoroughly clean without damage.A press after corn cob cleaning, prior to solvent washing. Corn cobs clean without scratching, and leave no residue. Loose paint, ink, grease, and residue is quickly removed without harm to the press. After a thorough detail hand cleaning, frames are disked smooth, fill coated, primed, then finished with Polane or your choice of polyurethane.

Press frames are stripped, abrasive blasted, fill coated, primed, and finished in polyurethane enamel, to OEM specs.

- Vehicle Refinishing

-

We water blast, sandblast, solvent clean, and disk sand. Corrosion resistant primers are applied. Finish coats are of the finest polyurethane enamels, formulated to your choice of color and sheen. Decals, stickers, and custom lettering available.

We water blast, sandblast, solvent clean, and disk sand. Corrosion resistant primers are applied. Finish coats are of the finest polyurethane enamels, formulated to your choice of color and sheen. Decals, stickers, and custom lettering available.

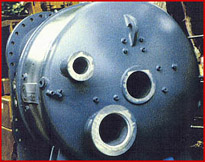

- Tank Lining

-

We specialize in corrosion resistant tank lining applications. All major industrial specifications are on file, including AWWA, FDA, USDA, and the Corps of Engineers.

We specialize in corrosion resistant tank lining applications. All major industrial specifications are on file, including AWWA, FDA, USDA, and the Corps of Engineers.Waste Water treatment tanks, constructed of carbon steel. Typical specifications: Interiors are fist solvent cleaned, to remove oils, then abrasive blasted to NACE #1, (SSPC-SP5) White Metal Blast Cleaning. Interior wetted surfaces are then coated with 16-20 mils DFT of polyamide coal tar epoxy. Exteriors are solvent cleaned, abrasive blasted to NACE #3, Commercial Blast Cleaning (SSPC-SP6), then prime coated with 4-6 mils DFT of poly-amide epoxy corrosion resistant primer, and finish coated with two coats of acrylic catalyzed polyurethane, in your choice of colors.

- Silo Painting

-

We specialize in cleaning and coating all types of storage silos. USDA, FDA, NSF, and other specifications strictly followed. Your schedule becomes ours. Silos are abrasive blasted or high pressure washed to a clean, sound surface suitable for coating. Rust resistant primers, epoxy or alkyd, are applied to assure corrosion resistance. Finish coats are formulated with polyurethane, for durability, color fastness, and gloss retention.

We specialize in cleaning and coating all types of storage silos. USDA, FDA, NSF, and other specifications strictly followed. Your schedule becomes ours. Silos are abrasive blasted or high pressure washed to a clean, sound surface suitable for coating. Rust resistant primers, epoxy or alkyd, are applied to assure corrosion resistance. Finish coats are formulated with polyurethane, for durability, color fastness, and gloss retention.Custom logos are computer designed for your silo. Size, location, colors, and proportions are exactly reproduced.

Lowest prices, highest quality.